In today’s highly competitive industry, engineers and designers need powerful tools that not only meet the requirements of complex product design but also simplify workflow and shorten time to market. Siemens’ NX modelling software is a solution that helps users solve the most complex design tasks accurately, efficiently and easily. From automotive to aerospace, NX modelling software helps companies leverage advanced technologies to improve designs. Let’s take a look at the key features of NX Cad Modelling Software and how they can transform your manufacturing process.

Advanced 3D Modeling

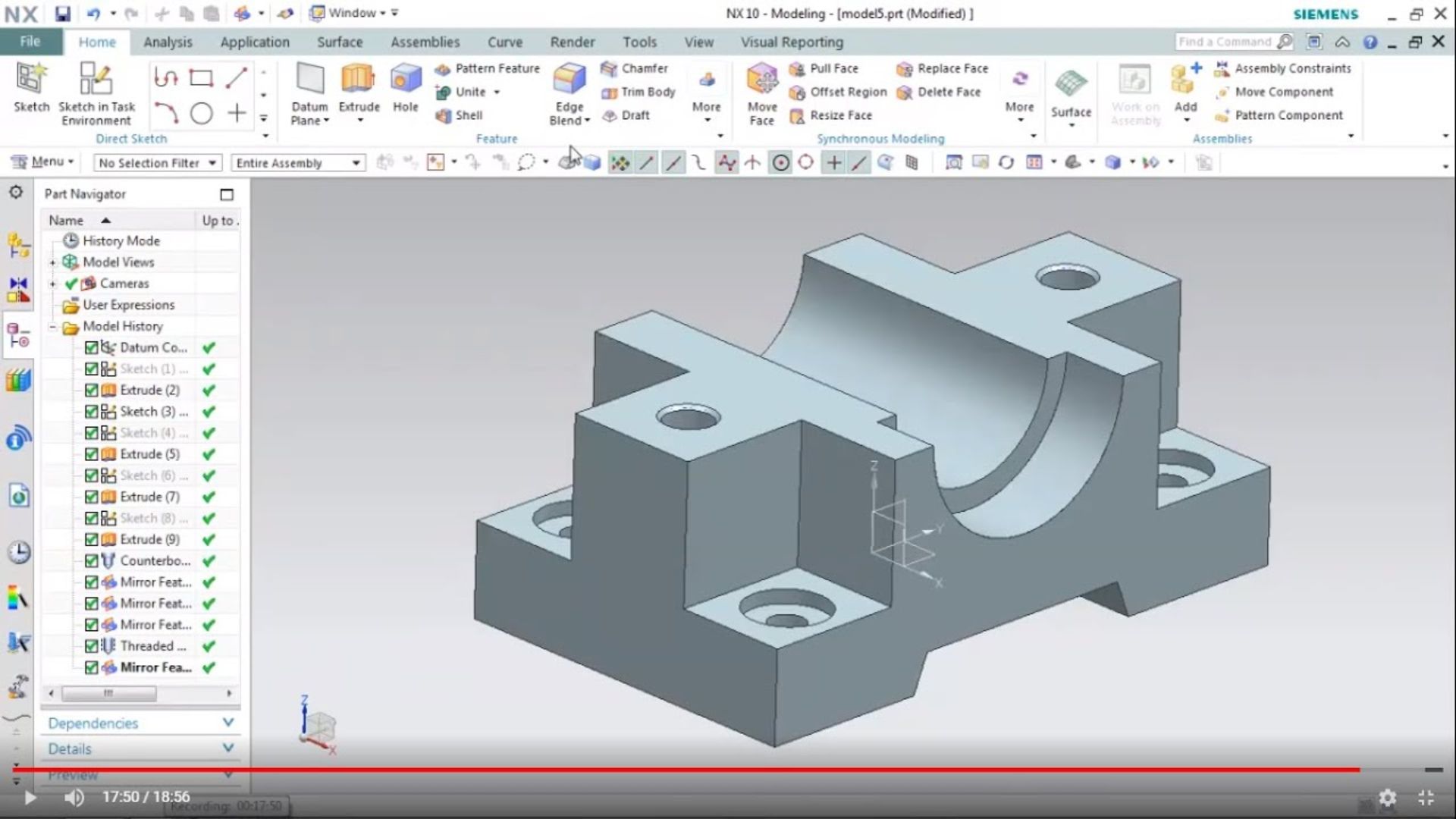

One of the most popular features of NX modelling software is its 3D modelling capabilities. Whether you’re building a simple part or a more complex model, NX provides the tools to accurately turn your ideas into reality. The software provides a parametric and precise design approach, enabling designers to create detailed models while maintaining control over design parameters.

The ability to switch between these types of displays makes NX very powerful. Parametric modelling enables precise control over measurements, while direct modelling enables rapid development, making it easy to change designs on the fly.

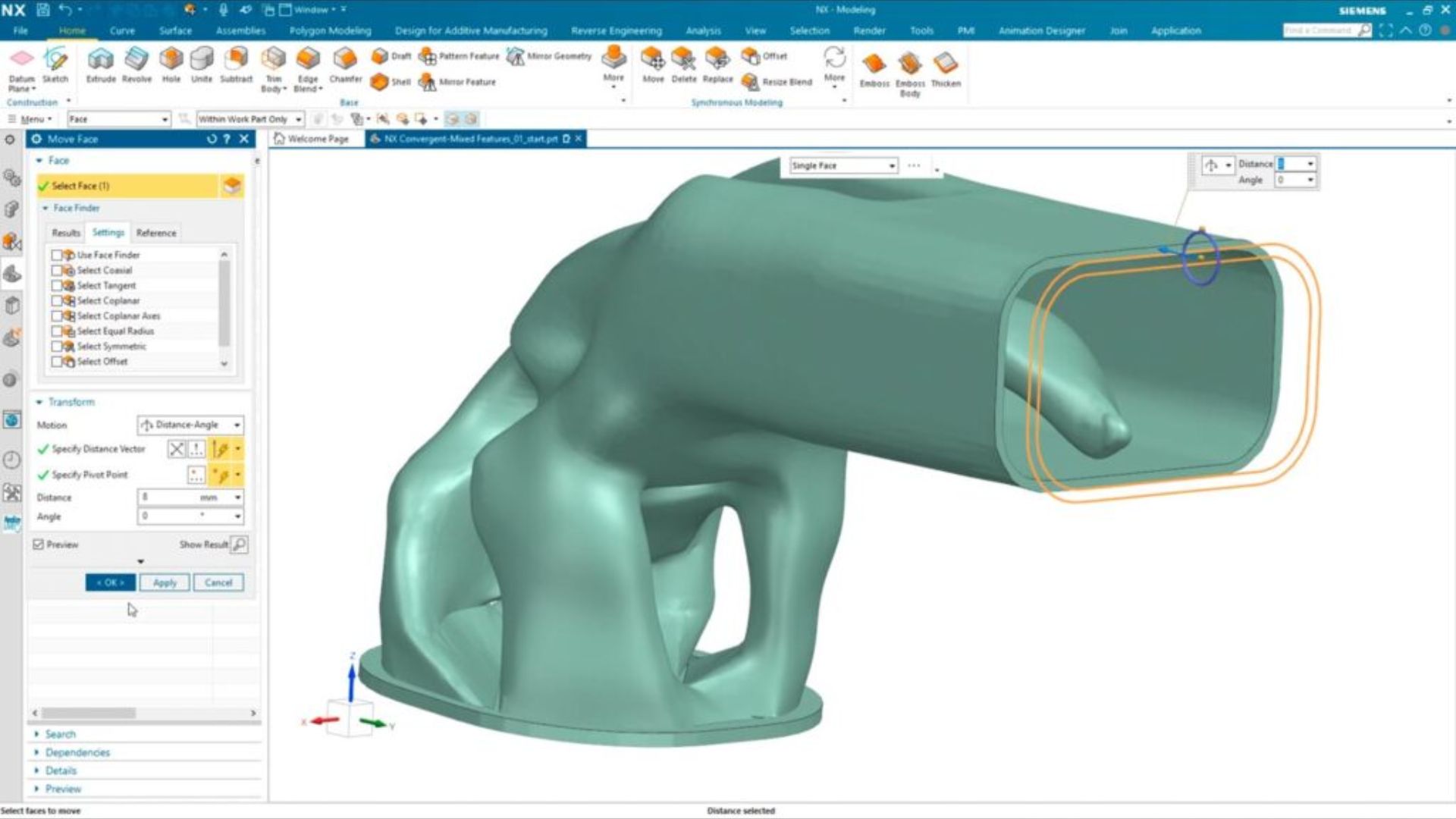

Synchronization technology for on-the-fly design editing

NX synchronization technology is a game changer for rapid designers. This new feature allows users to change their design without having to go back and change the entire interface. Designers can interact directly with the geometry and instantly change it while the software automatically adjusts shapes and constraints. This level of coordination speeds up the manufacturing process and reduces the time spent on tedious changes.

Synchronization technology can also integrate data from other CAD systems, enabling efficient collaboration with external teams. Designers can import models from a variety of software programs and edit them into NX models, reducing rework and speeding up project times.

Design and Assembly Management

Managing large assemblies containing thousands of parts is a difficult task, but NX modelling software and its powerful assembly tools make it easy. The software helps designers handle complex assemblies and maintain high performance even as the number of components continues to grow. The NX session management tool enables users to control all aspects of the design, ensuring that every element is in perfect working order.

NX is also able to manage interference and collisions between components, ensuring that the design is optimised for production before going into production. This reduces the risk of errors and rework, thereby saving time and money in the production process.

Surface and Sheet Metal Design

NX is the best modelling software for advanced surface and sheet metal design. For industries where geometric accuracy is critical, such as automotive and aerospace, NX provides advanced tools to help create complex shapes with high accuracy. Designers can easily control the space to suit the different features and functions of their products.

In addition, the NX Casting Interface allows users to create accurate cast parts, taking into account materials and manufacturing processes. These tools enable designers to create components that are not only functional but also optimised for manufacturing, thereby reducing manufacturing costs and increasing efficiency.

Conclusion

Siemens NX modeling software is considered a comprehensive and comprehensive tool that provides advanced capabilities for 3D modeling, assembly management, metal and paper design, simulation and engineering. With its parallel technologies, integrated CAD/CAM/CAE environment and customization options, NX can enhance designs faster, better and more accurately. By using NX modelling software, companies can take their designs and skills to the next level, ultimately making their businesses more efficient and effective.