Getting started with Product Data Management

Overview

Creating innovative products today requires companies to address a wide variety of issues and business challenges. A key challenge is marshalling the resources of the extended enterprise and efficiently using these assets to deliver the right products at the right time to the right markets.

Product and process knowledge is recognized as a key resource in achieving business success. But even in today’s digital age, most companies still struggle to utilize this knowledge as a manageable asset from one business opportunity to another.

Product data management (PDM) enables companies to manage all of their product and process -related knowledge in a single secure but accessible system that can be used by multiple applications and multiple teams across an organization. With a PDM system in place, product information assets can be coordinated and synchronized, enabling companies to:

- Improve productivity and reduce cycle time

- Reduce development errors and costs

- Facilitate collaboration with anyone, anywhere

- Improve value chain orchestration

- Provide greater visibility so they can make better business decisions

To deliver these advantages, companies need a PDM system that is able to support their business- specific needs. At its foundation, this system must be able to provide best-practice solutions for:

- Secure data management

- Process enablement

- Bill-of-materials visibility (configuration management)

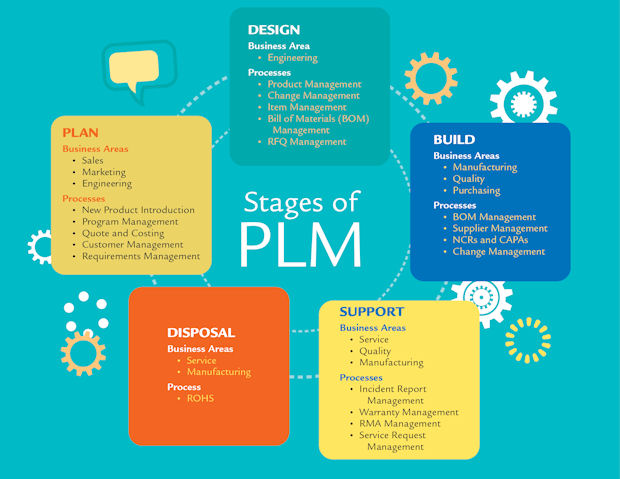

- Choosing the right PDM system provides companies with a solid foundation that can be easily expanded at their discre-tion into a full product lifecycle management (PLM) platform

Business Challenges

Companies are under constant competitive pressure to improve their top-line business results, realize bottom-line efficiencies and accommodate continually changing market demands. In addition, they are asked to meet increasingly stringent government and industry regulations. All of these challenges require companies to take full advantage of their product and process information.

Yet, in many of today’s companies, product and process knowledge is still spread across multiple systems, databases and desktops. A wide variety of tools and software applications are used to create this knowledge initially. Equally important, little or no connectivity is in place to tie these information assets together – even in product development operations, where different disciplines use different applications to create information in multiple formats.

The end result is a series of disconnected information “silos” that inhibit companies from reaching the productivity and time-to-market goals that are crucial to their strategic objectives. More specifically, it is difficult to coordinate and synchronize product and process information that is used to define the company’s product offerings and their related systems, assemblies, parts and components.

More and more enterprise participants need access to this information in formats they can understand so they can leverage it as early in the product lifecycle as possible. Seamless access to product requirements, designs, documents and 3D models enables all decision makers, stake-holders and lifecycle contributors – not just engineers – to make more informed and better decisions.

Business Needs Addressed by a PDM System

Secure data management

Which enables the Product Data Management (PDM) system to address multiple end user needs and experiences. A PDM system should be able to capture and manage all of the information required to design, develop and produce today’s products. Users across every stage of the product lifecycle need to be able to easily locate and work with the information required to get their jobs done, including parts, documents, requirements, electrical drawings, manufacturing instructions and other meaningful data. This access must respect the entitlements that protect the intellectual prop-erty rights and security needs of the enterprise.

Process Enablement

Which provides the Teamcenter PDM system with workflow and process capabilities needed to enable both internal product teams and external partners to participate in the product lifecycle Management. A PDM system should ensure that all processes are consistently managed through best-practice rules and conventions. A rules-based engine is especially valuable since it can be used to easily capture best practices and process knowledge and allow consistent execution with appropriate participants and data.

Bill of Materials (BOM) visibility

Which enables the PDM system to manage product information from wherever it is created while allowing it to be used wherever it is needed.

A PDM system should be able to manage information across an entire product lifecycle and bridge the gap between the upstream stages of the lifecycle and its downstream phases. The system also should enable participants in each stage to visualize and share information without requiring them to purchase or learn how to use special software. Just as importantly, the PDM system should provide total BOM visibility, which includes being able to see the bill of materials before and after changes are made, as well as from different points of view, including promoting understanding by non- technical users by enabling them to visualize the product’s parts in 3D.

You can know more about that how Siemens Teamcenter PLM data management system is helpful for your Data Management.